![]()

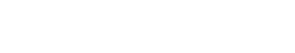

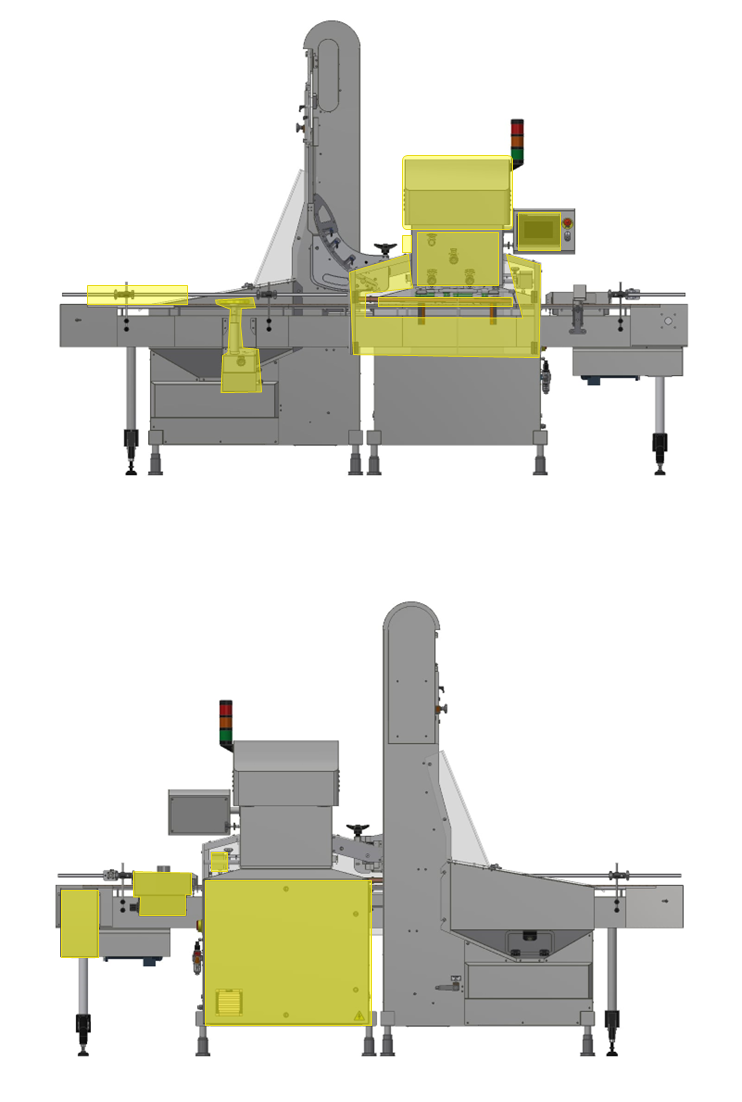

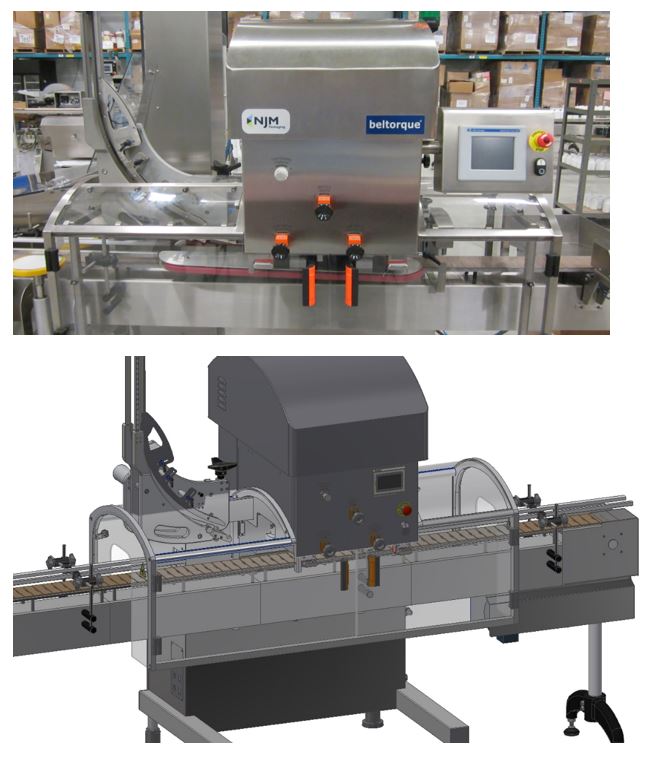

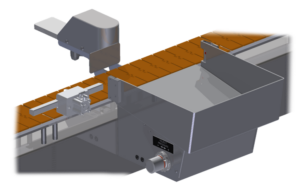

Upgrades available for the beltorque Capper/Retorquer

With the use of synchronized belts, the versatile and innovative beltorque capper from NJM applies cap torque without cap scuffing. Find below all of our aftermarket upgrades and obsolescence replacements available for the beltorque capper.

Mouse over or click any of the highlighted areas on the machine to learn more about the aftermarket products available.

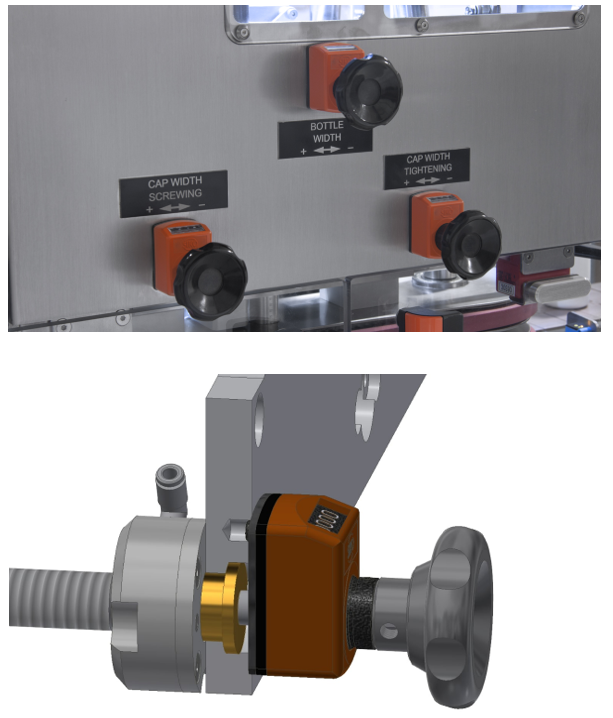

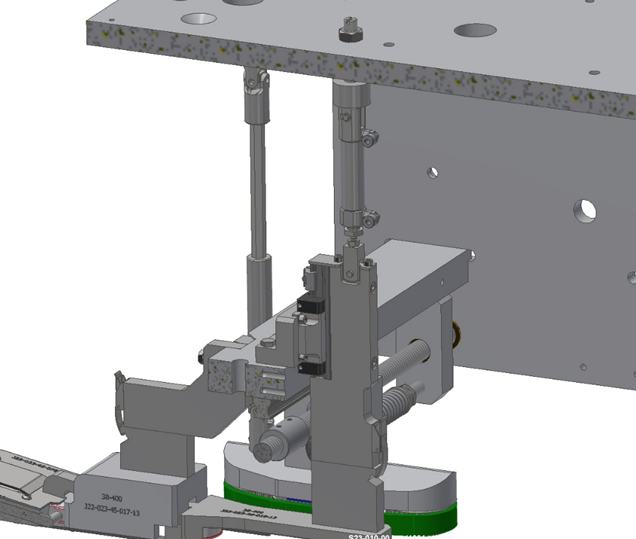

Motorized Screwing Station

A must for allowing caps, larger than 50mm OD, to be fully screwed before advancing to the tightening station.

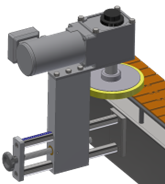

Belt Synchronization Supervisor

Keeps an eye on your set-up when belts start to wear down. The system will warn you if the belts start slipping on your cap so you can make the proper setup adjustment. This will increase belt life.

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

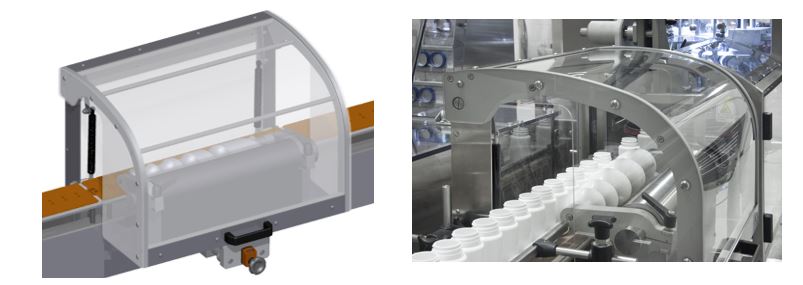

Line Clearance

Allows internal visual inspection to locate trapped tablets or help in maintenance execution.

Back to overall machine diagram ↑

–

–

–

–

–

–

Infeed/Outfeed Tunnel Guards

Benefits:

- Enhanced operator safety

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

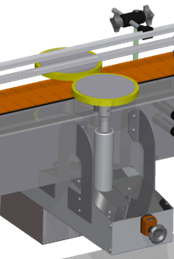

Separating Devices

Feedscrew

Starwheel

Friction Spacing Wheel

- Single

- Double

Holds on to heavy containers

- Double Spacing with Second Stage

Better control spacing for large and softer containers

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

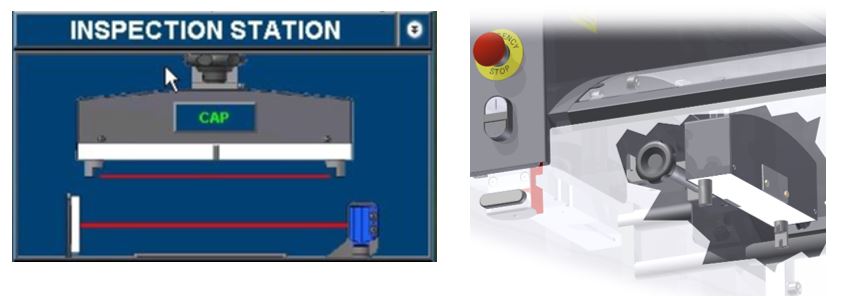

Inspection: Missing Cap / Missing Foil / Fallen Bottle / Cross Threads

Inspect your product before it gets to the next machine

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Reject Station

- Regular or Oversize Reject Bins

Reject bins can be adapted to all sizes and shapes to accommodate all needs

- Lockable Reject Bins

Make sure rejected product is securely isolated from good, inspected product

- Deviators to Prevent Tall Bottles from Falling

Better bottle handling to reject tall filled and unstable containers

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

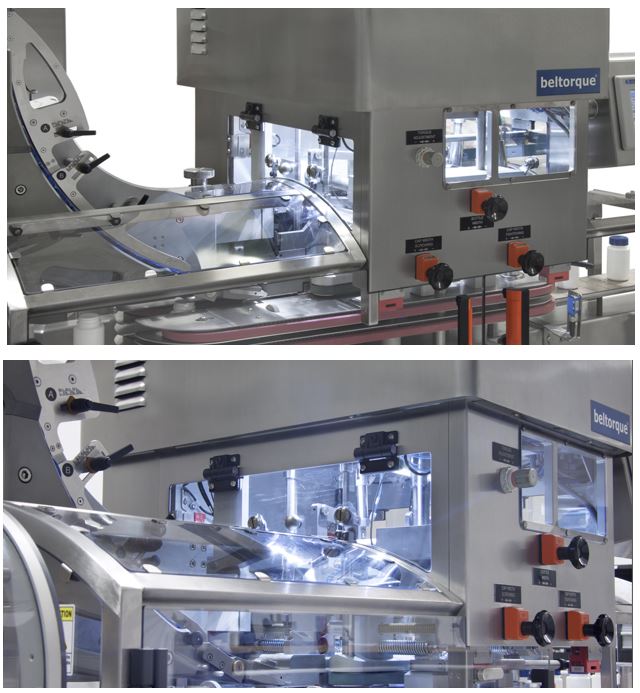

Swivel HMI Enclosure

Adding this feature will help in being more efficient when performing setup and provides access to the screen from both sides of the equipment.

HMI Upgrades

- PV Micro 300 Obsolescence

Prevent unscheduled downtime and upgrade your obsolete PV Micro HMI to the latest, larger and highly available Panel View HMI

- Size Upgrade from 4 Inches to 7 Inches

Improve visibility and operating efficiency

Torque Monitoring

Keep an eye on your torque and reject bottles outside the desired applied torque range. It’s all possible with the live torque monitoring system.

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Double Transport Belt for Tall Containers

Keep your tall bottles straight or softer containers well secured with the double transport belts.

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

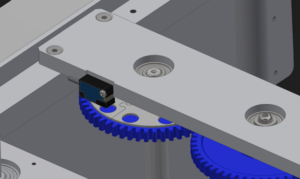

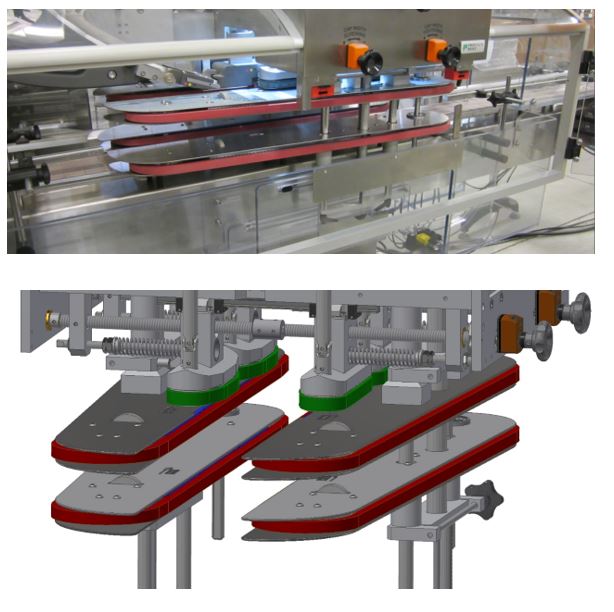

Auto Lock on Belt Adjustment

Adding this feature will prevent vibrations from adjusting your belt positions. This feature unlocks automatically once the machine stops

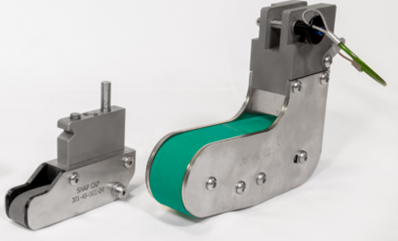

Snap Cap Accessories

Your capper can go beyond then just screwing caps! Inquire about all the possibilities.

Interior Lighting

- Keep an eye on the heart of your equipment to spot minor issues before they evolve to major breakdown.

- This lighting is also very practical to locate trapped tablets between product change-over and help in set-up.

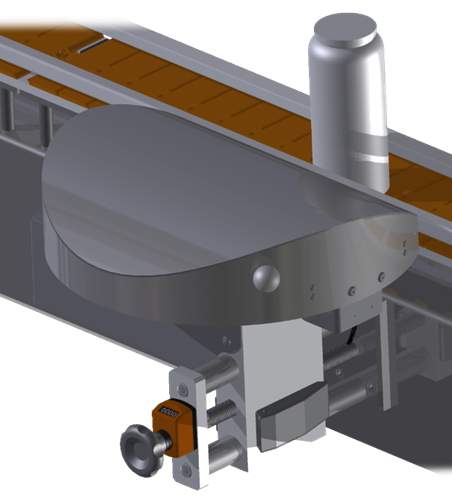

Assistant Plate Holder Retrofit

New holding system for a better control of your cap while screwing on the bottle and greatly reduces the possibility of cross threads.

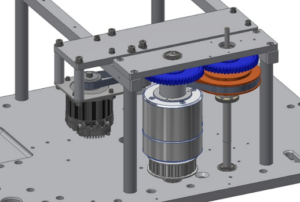

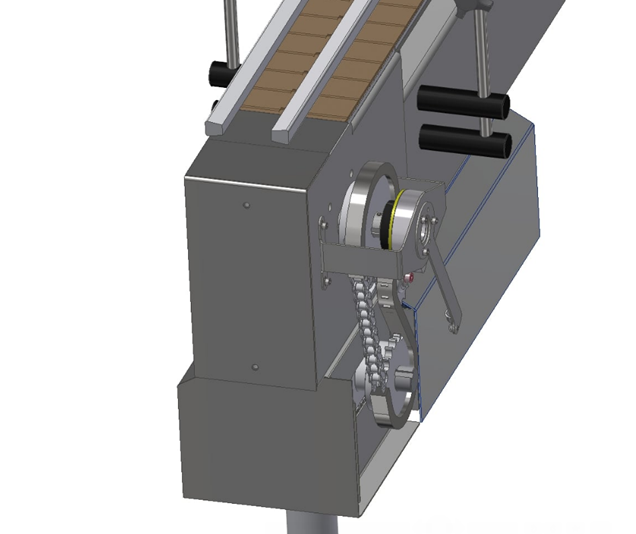

Oilless Synchro Bloc

New synchro block (part of our patented technology) free of oil. Eliminates the possibility of contamination due to an oil leak.

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Odd Format Product Handling System

Your beltorque can handle products you never thought it could!

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Conveyor Encoder

Add precision to your tracking and reduce human error.

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Up/Down Motorization for Obsolete 120 Vac System

New 24 vdc system. Easy straight forward retrofit.

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–