![]()

Upgrades available for the Cremer CF622

NJM is the exclusive representative and sales resource for Cremer tablet counters in the US and Canada. Find below all of our aftermarket upgrades available for the Cremer CFS622 and CFI622 models.

Mouse over or click any of the highlighted areas on the machine to learn more about the aftermarket products available.

–

–

Clear bottle USD (upside-down) sensor

An upgrade using ultra-sonic detection instead of the original USD sensor is available and makes clear glass or plastic bottle detection possible.

Benefits:

- Ability to reliably detect clear upside-down containers

- Prevent nozzle breakage due to collision with upside-down container

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

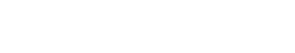

Minimum surface detection software upgrade

The Cremer tablet counter is not a sorting machine…it will count whatever is thrown its way, even broken tablets. Depending on piece size and geometry, this software upgrade can detect those pieces and reject the bottle that it is in or let it go through and not count the tablet piece as a tablet.

Benefits:

- Reduce the number of broken tablets going to your customers

- Stop counting broken pieces as tablets

- Deliver your customer a better product

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Reject System Upgrades

Double stack or broken tablets can lead to “miscounts.” Special trays with the reject system can improve the quality of the product you sell.

Benefits:

- Save on additional tablets in bottles due to undetected “overstack”

- Delivery of better quality due to reduction of tablet pieces in bottles

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

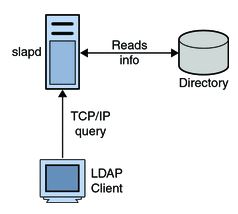

LDAP & OPC-UA Software System Upgrades

LDAP software upgrade

Use the company network Lightweight directory to create new users or modify access right to existing users/machine operators.

Benefits:

- Better managements of machine operator rights

- Better security

OPC-UA Software upgrade

With the OPC-UA software upgrade, customers interested in implementing OEE to promote efficiency are able to read values from the tablet counter to display status or statistics.

Back to overall machine diagram ↑

–

–

–

–

–

–

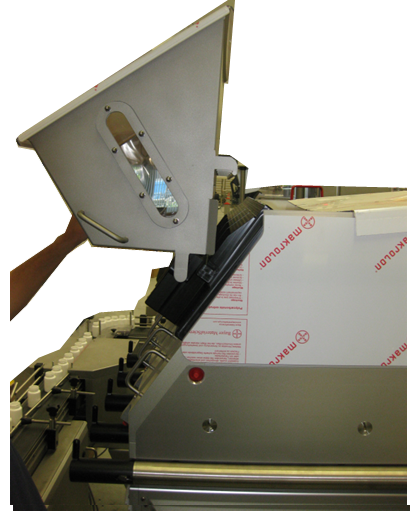

Tilting hopper system

Customers having a hard time installing or removing the hopper can upgrade their CFS622 to a tilting hopper. Installing or removing the hopper can become an easy one-person job.

Benefits:

- Eliminate possible hopper blocks breakage due to misalignments of hopper during installation or removal

- Ease of hopper installation

- Installation and removal of the hopper can be done by one person

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Static elimination upgrade

Customers having issues with tablets/capsules sticking inside the channel divider and creating “miscounts” may be facing static control issues. An anti-static bar can be added to reduce the static of products and eliminate “miscounts.”

Benefits:

- Increase count accuracy

Note: This solution can be implemented in conjunction with stainless funnels and anti-static channel divider front covers.

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–

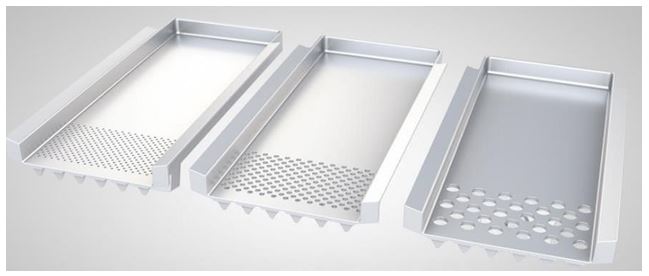

Sieve plates for broken products

The amount of broken products making their way into the bottles can be reduced by upgrading with specific design sieve plates.

Back to overall machine diagram ↑

–

–

–

–

–

–

–

–

–

–

–

–

–

–