>> Serialization under Drug Supply Chain Security Act (DSCSA)

>> Challenges in unique serial numbers, equipment and line integration, and aggregation

When implementing Serialization under Drug Supply Chain Security Act (DSCSA) in high-speed lines there are significant challenges for pharmaceutical manufacturers and contract packaging companies due to a combination of operational, technical, and regulatory factors.

A common issue is the management of unique serial numbers at the unit level. Every bottle or carton must be labeled with a serialized 2D data matrix code, printed in real time and verified with vision inspection systems. On high-speed lines running at 300 units per minute or more, without seamless integration and robust product tracking, mislabeling, product rejects or regulatory non-compliance issues can occur.

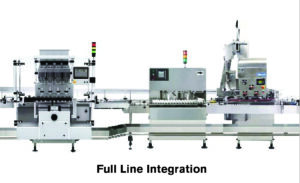

Another significant challenge is equipment and line integration. Serialization and aggregation must work seamlessly with equipment such as labeling machines and its controls platforms like PLCs, thermal or laser printers and vision systems. Aggregation also requires establishing parent-child relationships between units, bundles and/or cases, and pallets with advanced track-and-trace capabilities and precision vision systems. Data and tracking synchronization mismatches can cause delays and frequent stoppages which will directly impact the line Overall Equipment Effectiveness (OEE). NJM’s project management coordinates the necessary deliverables and testing required by the different vendors involved for a successful implementation.

Another significant challenge is equipment and line integration. Serialization and aggregation must work seamlessly with equipment such as labeling machines and its controls platforms like PLCs, thermal or laser printers and vision systems. Aggregation also requires establishing parent-child relationships between units, bundles and/or cases, and pallets with advanced track-and-trace capabilities and precision vision systems. Data and tracking synchronization mismatches can cause delays and frequent stoppages which will directly impact the line Overall Equipment Effectiveness (OEE). NJM’s project management coordinates the necessary deliverables and testing required by the different vendors involved for a successful implementation.

At NJM, we design and test our turnkey integrated packaging lines, labeling equipment, bottle handling systems, and implement vision inspection solutions for product Track and Trace while meeting performance and throughput needs.

Another competence of our team is RFID labeling, which can be an effective tool in DSCSA compliance for the following reasons:

-

Product Serialization & Identification

-

Improved Tracking and Tracing

-

Efficient Data Capture

-

Inventory Verification & Detection of Suspect Products

With an assessment of available floor space, user requirement specifications, and packaging components, our team provides innovative cost-effective line solutions. After a Factory Acceptance Test of the entire line at our purpose-built facility, NJM can install turnkey systems at the end user with training, documentation and validation support for all of our integrated packaging line equipment.

By managing the mechanical and automation aspects of the packaging line, NJM enables pharmaceutical manufacturers and CDMOs to concentrate on addressing their serialization challenges—such as implementing IT infrastructure and training for serialization workflows—ensuring seamless end-to-end supply chain traceability.

For more NJM news, click here.